news

October 3rd, 2024

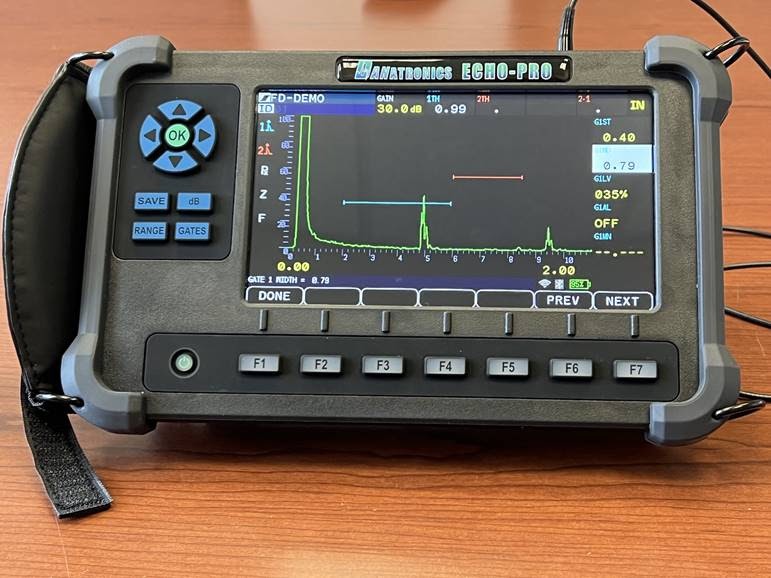

Danatronics is thrilled to announce the launch of ECHO PRO, our new portable ultrasonic flaw detector. Combining innovation with user-friendly functionality, ECHO PRO is the perfect solution for industry professionals seeking a reliable, intuitive portable instrument for flaw detection.

What makes ECHO PRO unique?

ECHO PRO sets itself apart by offering dual operation modes—touch screen and keypad—allowing users to choose based on their preference and application needs. Younger users appreciate the ease of touch screens, where dragging a gate or adjusting gain with a simple swipe feels intuitive. However, touch screens can sometimes present challenges, such as handling with couplant-covered hands.

Other devices limit you to keypad use only, often resulting in slower operation and a steeper learning curve. With ECHO PRO, Danatronics combines both touch screen and keypad options, delivering the best of both worlds. Whether you're tapping icons, dragging gates, adjusting range, or utilizing a responsive keypad with tactile feedback, ECHO PRO provides the versatility you need.

The user experience is seamless, with both input methods providing fast, accurate performance. Best of all, the keypad’s layout allows for easy operation with a single thumb, optimizing convenience without compromising functionality.

Applications

ECHO PRO is designed for a wide range of ultrasonic flaw detection applications, including weld inspection, de-laminations, porosity, and dis-bond analysis. ECHO PRO is utilized across industries such as oil and gas, refining, manufacturing, power generation, tank and pipeline inspection and thickness surveys.

Key Features of ECHO PRO

- 7” sunlight, bright touch screen display

- Color change and vibrate on alarm

- Durable, custom-designed case with IP67 rating

- 10+ hour continuous battery life

- 2 gates, DAC, TVG, data logging, and B-scan

- Peak Pitch Memory with audible chirp for signal peaking—an industry first!

- Four independent measurement boxes

- Automatic calibration

- Stores over 5,000 setups for quick and repeatable testing

- Future upgrades to include DGS, interface gate, floating gate, back echo attenuator, extended range, Bluetooth, and Wi-Fi compatibility

ECHO PRO is shipping now. Contact us today to get a demo, quote or to learn more about the ECHO PRO!

Celebrating 20 years!

March 13th, 2024

They say “time flies” when you're having fun...

They say “time flies” when you're having fun...It's hard to believe Danatronics™ is celebrating our 20th year in business! Since the very beginning, we have stayed true to our core values of always putting our customers first without exception

In an effort to show our appreciation and gratitude to the thousands of customers who have trusted us with their critical asset testing, we are offering a special promotion through the end of June.

Our "20 for 20" promotion is a one time, 20% discount off any of our ultrasonic or magnetic thickness gages. Simply mention this promotion, place your order, and we will do the rest in the timely fashion that you have grown accustomed to.

We also want to send a heartfelt thank you to our customers for your loyalty and confidence in us, and to our employees for your dedication and hard work. Cheers to the next 20!

Rules & Exceptions

- Single use offer

- May only be applied to one gage

- US & International Agents are eligible - discount taken off current buy price

- OEMs are not eligible

- ECHO-PRO is excluded from this promotion

- Offer valid through June 30, 2024

Introducing ECHO Pro

November 21st, 2023

We've been hard at work creating our newest Flaw Detector, ECHO Pro!

We're excited to be able to share some initial details. A full spec list will be coming soon and we expect to start shipping around the end of Q1 2024.

Key features of ECHO PRO

- Bright, sunlight readable 7” Wide VGA touch screen display

- More than 8 hour battery life

- Keypad and Touchscreen operation

- Standard features include datalogging, 2 gages, DAC, AWS, B-scan, API-5Ue

- Advanced features include extended range, TVG, Back ECHO Attenuation, Interface Gate, Wi-Fi, Bluetooth, Damping and Energy Intuitive user interface combining touchscreen or keypad

- Custom packaging with rubber bumpers, hand strap, neck harness, variable angle hinge/stand and magnetic pipe stand

- Change color and vibrate on alarm

- Adjust gain, gates, delay and range from touch screen

Danatronics History

May 24th, 2022

We have been asked many times to share the story of Danatronics, so get ready for the

unbelievable tale of the innovative company from Danvers.

Dr Edmund H Carnevale founded Panametrics in December,1960 with two other gentlemen. They

picked the old Waltham Watch Factory as their home. After investing a mere $300 each, they grew

the business to include three divisions, NDT, PCI and Space/Science (R&D). Panametrics further

expanded to 14 worldwide subsidiaries and held more than 40 patents.

Ironically, Dan Carnevale and Yogin Patel started in the thickness gage group, one in sales and the

other in hardware development.

At the end of 2001, Panametrics employeed over 1250 worldwide.

Stay tuned next week for the history of Dan and Yogin’s time at Panametrics and the major events

that changed the UT world.

In 1983, Dan Carnevale joined Panametrics as a Sales Engineer after attending Boston University. He

rose to Manager of Flaw Detector Sales after the introduction of the first digital flaw detector, the Epoch

2002. He then became the Sales Manager, International Sales Manager and finally VP of Sales and

Marketing.

Yogin Patel, after also attending Boston University, joined Panametrics in 1989 as a Hardware

Development engineer. He remained in the engineering group and promoted to Director of Hardware

Development.

With Dr. Carnevale planning to retire, Panametrics was acquired by GE Power Systems in June, 2002.

Dan was promoted to Global Sales Leader and Yogin remained Director of Hardware Development until

his departure in 2004.

Rapid changes and the dismantling of loyal employees was difficult to witness. Around this same time,

GE Aviation had purchased Agfa/Krautkramer. GE now owned the two largest ultrasonic manufactures

in the world. As a result of this transaction, Dan tendered his resignation. The FTC and EU could not let

this stand, and GE Panametrics NDT was sold to RD Tech in Quebec.

In April, 2004 Danatronics, originally Danametrics, was formed and Danatronics brought on Yogin Patel

as the Chief Technology Officer. Together with Dan, they represented more than 4 decades of world-

wide experience in the design and sales and marketing experience in the portable ultrasonic

instrumentation market. True to their beliefs, they first embarked on producing a small but innovative

product, they got to work designing their first ultrasonic gage. This represented the core values of

design philosophy: easy to use and extremely innovative. In the early years, borescopes and video

probes were also offered as a compliment to their planned NDT line of products.

The EHC-09 was the first ultrasonic gage produced. Because family meant so much, the significance of

the first UT gage’s name was important. EHC stands for Dr. Edmund Henry Carnevale, Dan’s father’s

initials and the #9 was the number Dan wore throughout his hockey career in high school and in college.

After a year and a half of development, the EHC-09 was released. It was very well received and quickly

updated to include a Datalogger and Waveform, the world’s smallest gage with a waveform at that time.

The EHC-09 was the first gage in the world to Vibrate on Alarm, an innovative feature that is offered in

the majority of our product line today. Also, they introduced the world’s first sunlight readable Color

Display with waveform, giving a larger display for technicians.

In August, 2005, Dan brought on Nicole Hendrickson to run the front office, a position she still holds

today. Nicole wears many hats and is likely the first person you speak with when calling Danatronics. She

is an integral part of our team.

June, 2009, Danatronics moved its offices to its current location at 150 Andover St., Danvers, MA. The

new facility gave each department their own space and also added a conference room.

Danatronics first flaw detector, released in 2011, was the innovative iFlaw. The iFlaw had a 7” sunlight

readable Touch Screen and a built-in gyroscope allowing either portrait or landscape screen displays.

The iFlaw had a very powerful 600v pulser and 32G Sd card for data storage.

Also in 2011, Philip Jones joined Danatronics as an Electronics Lab Technician, a position he still holds

today, assembling gages, performing repairs and all other hardware related projects.

Courtney Carnevale Shakespeare joined Danatronics in Sept, 2013 as Quality and Logistics Manager. Her

addition continues the family legacy started by her grandfather.

Every gage that goes out the door to our customers, passes through her hands. She ensures the

Danatronics quality standards are met before shipping.

The newest ultrasonic gage designed and manufactured by Danatronics is the Echo 9DLW, released in

2015. Its most unique feature is that it can be upgraded, in the field, to a precision thickness gage and a

flaw detector. Three gages in one package are the most innovative design in conventional ultrasonics

today. The Echo also has a 27hr rechargeable battery for unmatched performance.

Adding to the Danatronics personnel, Larry Gochnauer was added in Jan, 2018 as their Sales Manager.

Danatronics will continue to grow and provide the most innovative instruments for the future.

The Danatronics mission statement: “To provide the highest level of product innovation and quality as

well an outstanding level of customer satisfaction”.

Lets see what the future holds………….

DataXL Mobile Now Available for iOS/iPadOS

June 22nd, 2021

We're excited to announce the release of DataXL Mobile, for iOS/iPadOS. You can now find DataXL mobile for iOS/iPadOS in the App Store along with the Android version that can be found in the Google Play Store.

DataXL Mobile harnesses the bluetooth feature to export data such as thickness readings or files to iOS or Android devices giving users the ability to setup files and view readings all from their mobile devices. DataXL Mobile is available free for ECHO Series and MTG-99 gages with bluetooth and is coming soon to IOS.

Want to add Bluetooth to your ECHO or MTG-99 gage so you can use DataXL Mobile for Android? Contact us today!